Photos

Applicatiion:

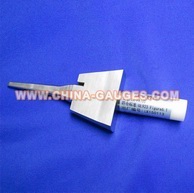

Ball Pressure Apparatus for Fire Hazard testing is used to test the heat resistance of non-metallic materials and solid electrical insulating materials except ceramics. Enclosures and other external parts of insulating material are subjected to the test. The ball pressure apparatus is designed to verify the quality and safety characteristics of products, as required by national & international standards.

Construction:

- ball holder with bore and clamping screw for the bow

- Precision 5mm pressure ball

- Thermocouple for the test stand

- Nickel plated steel materials for good thermal stability

Technical Parameters:

| Ball diameter | 5mm (R2.5mm) |

| Total test pressure | 20N±0.2N |

| Samples bearing | diameter 50mm, length 100mm, solid stanless steel cylinder |

| Production of materials | all used stainless steel materials |

| Remark | Ball pressure instrument takes another a hot box (oven) supporting the use. |

Conforms to:

IEC60238, IEC60309, IEC60320, IEC60335, IEC60598, IEC60601, IEC60669, IEC60670, IEC60745, IEC60884, IEC60950, IEC60998, IEC61058, IEC61558.

Resistance to heat

Self-ballasted lamps shall be sufficiently resistant to heat. External parts of insulating material providing protection against electric shock, and parts of insulating material retaining live parts in position shall be sufficiently resistant to heat.

Compliance is checked by subjecting the parts to a ball-pressure test by means of the apparatus shown in figure 4.

The test is made in a heating cabinet at a temperature of (25 ± 5) °C in excess of the operating temperature of the relevant part according to clause 9, with a minimum of 125 °C for parts retaining live parts in position and 80 °C* for other parts. The surface of the part to be tested is placed in the horizontal position and a steel ball of 5 mm diameter pressed against this surface with a force of 20 N.

The test load and the supporting means are placed within the heating cabinet for a sufficient time to ensure that they have attained the stabilized testing temperature before the test commences.

The part to be tested is placed in the heating cabinet, for a period of 10 min, before the test load is applied.

If the surface under test bends, the part where the ball presses is supported. For this purpose if the test cannot be made on the complete specimen, a suitable part may be cut from it.

The specimen shall be at least 2,5 mm thick, but if such a thickness is not available on the specimen then two or more pieces are placed together.

After 1 hour the ball is removed from the specimen which is then immersed for 10 s in cold water for cooling down to approximately room temperature. The diameter of the impression is measured, and shall not exceed 2 mm.

In the event of curved surfaces the shorter axis is measured if the indent is elliptical.

In case of doubt, the depth of the impression is measured and the diameter calculated using the formula f = 2 p (5 - p) , in which p = depth of impression.

The test is not made on parts of ceramic material.

HK LEE HING INDUSTRY CO., LTD are specialized in manufacturing special, custom built, test and measuring equipment for products testing as per international norms and offering calibration services and related information. Our products and services are used by research & development establishments, test laboratories, defense establishments, government institutions & manufacturing industries to fulfill the clients' requirements.

Main Products: go not go gauges, IP Tester, test probe Kit, Impact Test Equipment, Test Probes, Spring Hammer, IEC 61032 test finger, AC Hipot Tester, IEC Test Probe, UL Test Probe, Material Flammability Tester, IP Code Tester, Impact Test Apparatus, Plugs and Socket Outlet Gauge, Security Testing Machine, Lamp Cap Gauge Tester, Lampholders Gauge Tester, Plug & Socket Tester, Electrical Safety Tester, LED Test Instruments, Environmental Test Equipment, Instrument Accessories, Weighing Sensor and More.

If you require equipment to test products such as home appliances, electrical accessories like switches, sockets, connectors, etc. industrial & road lighting luminaires, automobile lighting systems or related categories, we can provide the solutions you need.

We would appreciate your comments on the layout design, presentation or other aspects of our website.

Website: http://www.qiyingwork.com

Contacts: Eason Wang

E-mail: info@iec-equipment.com

TEL: +86-755-33168386

FAX: +86-755-61605199

Phone: +86-15919975191

SKYPE: carlisle.wyk

Address: 1F Junfeng Building, Gongle, Xixiang, Baoan District, Shenzhen, Guangdong, China

ZIP: 518102

Website: http://www.qiyingwork.com/

Categories

Latest News

Contact Us

Contact: Eason Wang

Phone: +86-13751010017

Tel: +86-755-33168386

Add: 1F Junfeng Building, Gongle, Xixiang, Baoan District, Shenzhen, Guangdong, China

Eason Wang

Eason Wang